PAINT TEST EQUIPMENT

|

Coating Thickness MeterThe Coating Thickness Meter will measure all coatings on metallic substrates using the magnetic induction or eddy-current principles, ensuring the correct coating thickness has been applied. |

|

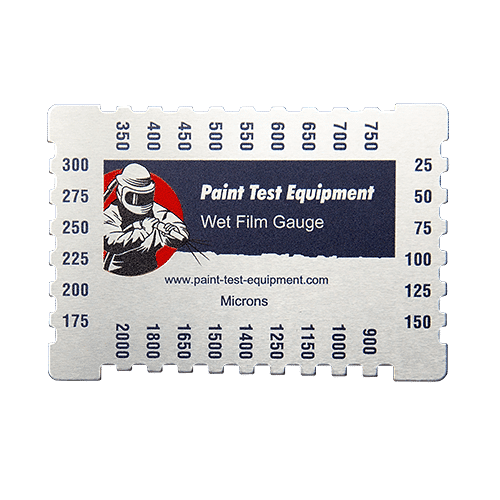

WET FILM GAUGENEW Wet Film Gauge will measure the paint thickness while the coating is still wet. Manufactured in aluminium, the Wet Film Gauge can either be kept has a record for the wet film thickness taken or cleaned in solvents and reused. Supplied in packs of 10. Compliant to ISO 2808 and ASTM D4414. |

|

PAINT INSPECTION KITPaint Inspection Kit offers the industrial painter all the essential equipment needed for the testing of blast-cleaned steel prior to the protective coating application. When steel has been blast-cleaned to a surface preparation of Sa 2½, the inspection of the steel to ISO Standards is required. This ISO Standard compliance ensures that blast-cleaned steel is correctly prepared for the application of protective coatings. Supplied in an industrial Carrying Case with Testex Replica Tape / Replica Tape Gauge, Bresle Patch Test, Dust Tape Test, Dewpoint Meter, Coating Thickness Meter and Wet Film Gauge (pack of 5). Calibration Certificates with traceability to UKAS are an optional extra. |

|

HOLIDAY DETECTORThe Holiday Detector is a DC Holiday Tester for detecting pinholes and flaws in coatings on conductive substrates. Available in the following Holiday Detector models: S4001 0.5–6kV for coatings up to 1100μm, S4002 1–20kV for coatings up to 3700μm and S4003 1–30kV for coatings up to 8000μm.Where coatings have to provide an effective safeguard against corrosion, it is essential that any pinholes or flaws that will eventually lead to corrosion are detected at the earliest possible stage. Supplied in an industrial Carrying Case with High Voltage Handle, Band Brush Probe, Earth Cable (10m) and Carrying Bag. Calibration Certificate with traceability to UKAS is an optional extra. Compliant to the following Standards: ISO 29601, ISO 2746, ASTM D5162, ASTM G62, NACE SP0274, NACE SP0188 and NACE SP0490. |

|

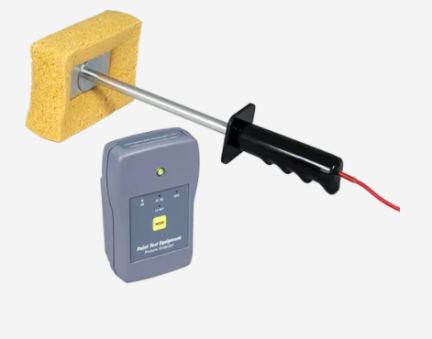

PIN HOLE DETECTORPinhole Detector for detecting pinholes and flaws in coatings on conductive substrates.These flaws would eventually lead to corrosion and premature failure of the coating. Supplied in an industrial Carrying Case with Sponge Assembly and Earth Cable (5m). Calibration Certificate with traceability to UKAS is an optional extra. Compliant to ISO 29601. |

|

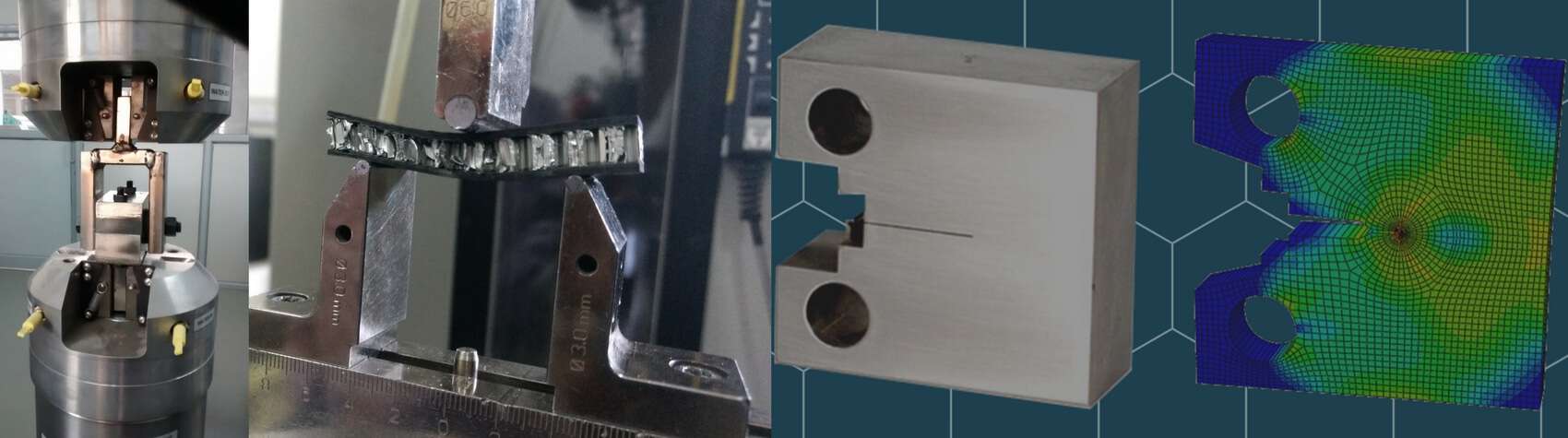

Adhesion TesterThe Adhesion Tester will measure the adhesion bond strength of applied coatings on flat and curved surfaces by the tensile pull on a Dolly glued to the coating. Supplied in an industrial Carrying Case with 5 Flat Dollies, Turbo Fuse Adhesive, Dolly Cutter, Heated Dolly Remover, Dolly Cleaning Tool, Dolly Plug. The Calibration Certificate with traceability to UKAS is an optional extra. Compliant to ISO 4624, ISO 16276-1 and ASTM D4541. |

|

Cross Hatch CutterCross Hatch Cutter is a multi-blade cutting tool which enables an assessment to be made of the adhesion resistance of coatings to separation from substrates.The coating thickness determines the Cross Hatch Cutter size used. The 1mm Cross Hatch Cutter is suitable for coatings under 60 microns. The 2mm Cross Hatch Cutter is suitable for coatings over 60 microns.Supplied in an industrial Carrying Case with Adhesion Test Tape (60m) and an x3 Illuminated Magnifier. Compliant to ISO 2409 and ISO 16276-2. |

|

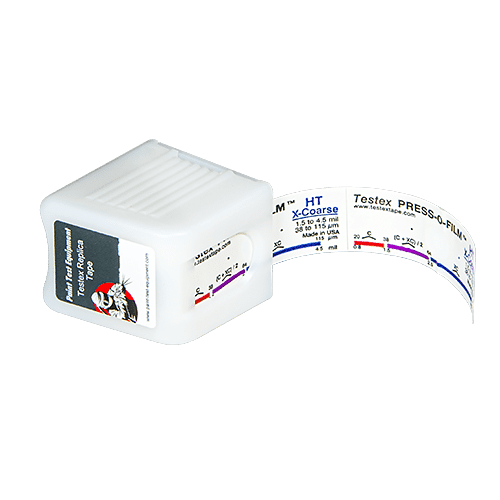

Testex Replica TapeThe Testex Replica Tape when used with the Replica Tape Gauge will measure the surface profile of blast-cleaned steel.The Replica Tape Gauge is used to measure the Testex Replica Tape replica and determine the average maximum peak-to-valley height of the blast profile. Supplied in rolls of 50 impressions. Compliant to the following Standards: ISO 8503-5, ASTM D4417 and NACE SP0287. |

|

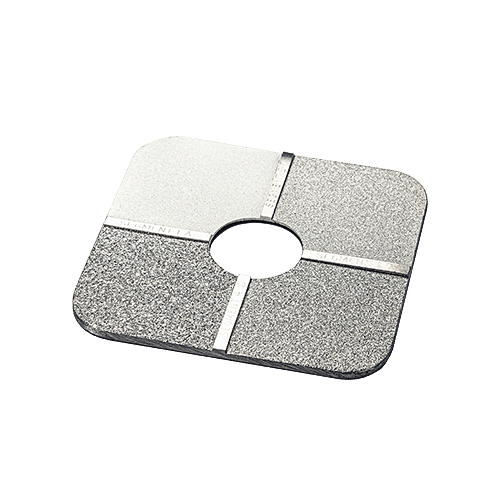

Surface Roughness ComparatorSurface Roughness Comparator for grit-blast and shot-blast surface profile comparison measurement of blast-cleaned steel.The Surface Roughness Comparator is supplied in a protective Wallet. Compliant to ISO 8503-1, ISO 8503-2 and ASTM D4417. |

|

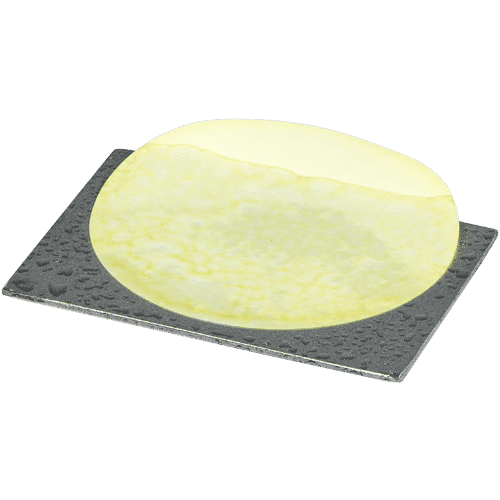

Bresle Patch TestThe Bresle Patch Test using the Bresle Patches will allow you to extract salts from blast-cleaned steel and measure using the Horiba Conductivity Meter.If these contaminants are not removed prior to painting, chemical reactions can result in blister formation and accumulations of rust that destroy the adhesion between the substrate and the applied protective coating. The Bresle Patch Test is supplied in an industrial Carrying Case with Bresle Patches (pack of 35), Horiba Conductivity Meter, Deionised Water (500ml), Syringe with Needle, 1413μS/cm Calibration Solution (14ml), Conditioning Solution (14ml) and Beaker. Conductivity Meter Calibration Certificate with traceability to UKAS is an optional extra. Compliant to the following Standards: ISO 8502-6 and ISO 8502-9. |

|

Potassium Ferricyanide PapersPotassium Ferricyanide Test Papers will detect iron salts that form at the bottom of rust pits on blast-cleaned steel.If these iron salts are present, they rapidly induce corrosion.The test involves the reaction of soluble ferrous iron salts with potassium ferricyanide to form ferric hexacyanoferrate, which is commonly known as Prussian blue. The relatively high tinting strength of Prussian blue enables the reaction to be used as a very sensitive test on ferrous irons. Supplied in packs of 100 Papers. |

|

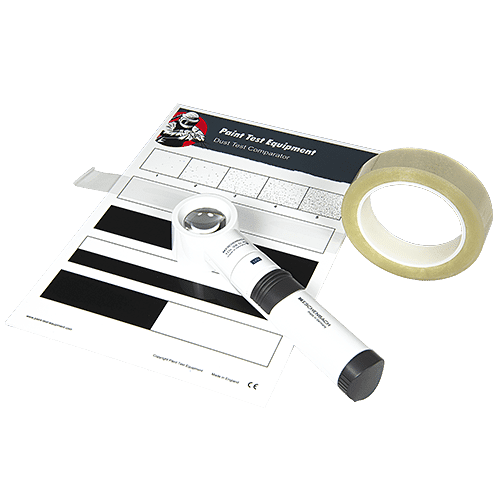

Dust Tape TestDust Tape Test using the Dust Test Tape and Dust Test Comparator will allow you to assess the quantity and size of dust particles on blast-cleaned steel.Dust particles on blast-cleaned steel surfaces may reduce the adhesion of applied coatings, and by absorbing moisture may promote the corrosion of the steel surface.All items are supplied in an industrial Carrying Case with Dust Test Tape (60m), Dust Test Comparator and X10 Illuminated Magnifier. Compliant to ISO 8502-3. |

|

Dewpoint MeterDewpoint Meter enables testing for the estimation of the probability of condensation on a surface to be painted and establishing whether conditions at the job site are suitable for painting or not.The steel surface temperature generally should be at least 3°C above the dew point when paints are applied. Below this temperature, the Dewpoint Meter will sound an alarm and the display colour will change to warn you that the surface conditions are not suitable to paint. Supplied in an industrial Carrying Case with Humidity Sensor. Calibration Certificates are an optional extra. Compliant to ISO 8502-4. |

|

Gloss MeterGloss Meter will measure the gloss of a surface where an aesthetic appearance of the coating finish is required.Gloss is measured with angles of 60° and 20°. The 60° angle is universal for all applications. The 20° angle gives improved differentiation of measurement on high-gloss coatings above 70 gloss units. Supplied in an industrial Carrying Case with Gloss Tile and Charger. Calibration Certificates with traceability to BAM are an optional extra. Compliant to ISO 2813. |