Hardenss Tester

Brinell Hardness Testing machine with Optical Device.

Features :

FTM has developed Briell Hardness Testing Machine with optical device.Basic machine design and operation is very simple and user friendly and its built with on optical device of 14X magnification provided in the elevation part to project diameter of ball intentor impression on glass screen with a adaptable and ergonomic micrometer measuring system with 0.01 mm least count .In this machine the indentor swivls and projects diameter of ball impression immediately after unloading operation which avoids additional time for measurement of ball impression. This is a production testing machine. Most suitable for foundry, casting industry, Heat treatment industry, Material Testing laboratories.

Computerized Brinell Hardness Testing

Features :

- Fully computerized system for indentation measurement and display

- Accurate measurement of Brinell Hardness through matched Optics, CCD Camera, hardware and software using advanced image processing technologies

- Wide range of testing with 4 load steps

- High accuracy confirming to IS 2281-1983

- Hydraulically loading / unloading system provided with load / unload knob for operation

- Windows based software system

- Three modes of measurement, manual, semi auto and auto

- In auto mode the image is scanned for measurement and hardness is displayed automatically. In Semi automatic mode curser is to click on the indentation to get the hardness value. In manual mode curser is to be matched to the diameter of the indentation to get the hardness value

- Calibration mode is provided with password protection

- Batch testing facility is provided

Description :

B-3000 PC Computerized Brinell Hardness tester has a C type load frame. The job is positioned on the test table and lifted by the hand wheel to touch the support plate. Required load is applied on the job and removed by operating Load / unload knob provided on machine at the bottom side of load frame. The timely indexing of indentors is automatic.

On removal of load the optics will transfer the image of indentation to COD. The image is further digitalized and processed by PC for measurement. The diameter of the image can be measured automatically / semi automatically / manually to give Brinell Hardness value.

The test report consists of Machine, sample and test details along with

- Mean diameter

- Brinell Hardness value

- Bitmap image

- Low / high limits acceptance and accept or reject status

Brinell Hardness Tester with Fully Automatic A-3000-IPC

General :

Computerized Brinell Hardness Tester, Model : B-3000-IPC is designed for Brinell hardness measurement on steels and other ferrous materials and also on non- ferrous materials like Brass, Bronze, Aluminium, etc. The material can be cast, forged or rolled and the shape can be flat, round or irregular shapes.

Features :

The actual load application system is of dead weight type combined with mechanical lever system. The supporting hydraulic system is for initial lifting of load before each test and dampening the load application system for smooth application of load.

A separate hydraulic power pack, positioned in the bottom part of the machine adds to the machine stability.

Our unique design of a floating fulcrum lever system ensures high accuracy and dependability. An automatic indenter index system is provided which tilts the indenter after the impression and the magnified image is visible on the IPC for area measurement & display of hardness value. Thus this machine saves a lot of cycle time, improves accuracy of measurement and gives fast and accurate results with less operator fatigue.

This model is mainly useful for production testing in Auto shops, Foundries, Forging Shops and Heat treatment units, etc.

The machine accuracies confirm to IS: 2281 2005 & BS : 240.

Special Additional Features :

- Machine has fully computerized system for indentation measurement and display.

- The image is scanned for measurement and hardness is displayed automatically.

- Accurate measurement of Brinell hardness through matched optics, CCD Camera with box image magnification, hardware and software using advanced image processing technology.

- It gives an image of indentation directly on inbuilt Industrial PC of the machine with measurement facility and touch screen.

- Fine adjustment facility is provided for accurate measurement of the image.

- Auto, semi-auto and manual test facility

- Quick compare mode for Go: No-Go application.

- Coarse and Fine position adjustment for manual test.

- Calibration modes Camera, Axial & Radial Calibration (5 Point calibration)

- Magnification of CCD Camera

- Magnification Of Objectives (5X, 10X,etc.)

- Focal distance (Radial Calibration)

- ERMA Scale ( X-Y Axial Calibration)

- Testing area (pixel Calibration)

- Batch testing facility

- Statistical analysis.

- Search based on various parameters.

- Software compatibility with Windows XP-SP2, Vista, Win-7 OS.

- Roll based access to features.

- Certificate generation.

- Test report, certificate printing facility.

Industrial Panel PC Specification :

- Fanless PanelPCwith 4 :3 LED touch screen panel and industrial motherboard specially designed for industrial applications.

- IntelAtom Processor 1.6 GHZ,1GBDDR2RAM.

- 8.0 LCD monitor having resolution 800 x 600 (SVGA)

Software Feature (BIMS):

This is precise Brinell Impression Measurement Software. High technology image management system is built to get desired accuracy with IS compliance to be measured within given time. The detailed features are as listed below :

Precise Brinell Impression Measurement :

Based on Image Processing techniques, BIMS achieves high precision image measurement and also the repeatability in the readings. It is easily configurable for environment. Working with USB camera enables BIMS to be deployable at difficult measuring conditions along with standard BIMS applications.

Measurement Modes :

There is a fast and accurate Auto mode for standard components with good surface finish. Additionally, a Semi-Auto mode is provided for measuring blured images due to poor surface finish. In case of very fast measurement requirements where the actual hardness value is not required. A confirmation that it is within specified limits is enough, compare mode is also provided. With such variety of modes, most of the test conditions are covered enabling the user to obtain results in required methodology and in required formats. Calibration Facility : Calibration is the heart of every measurement. So,BIMS provides multiple calibration levels to achieve high accuracy in results.There is Pixel calibration accompanied with multi-point calibration andERMAcalibration. With these calibration techniques, provides precise measurement results.

Analysis and Reporting : If one cannot find the historical data, it is as good as unavailable. So, Search is key feature of .BIMS Test Certificate and Customer are key search criteria along with other details. Uniqueness of the Test Certificates being generated is maintained and the same is available for searching and printing.Additionally, there is statistical analysis available in tabular and graphical formats to assist the user.

Hardware Interface : The key input to BIMS is the image captured by the CCD camera. So, presently it is configured to work with special purpose USB camera for this application.

Digital Motorized Rockwell Hardness Testing Machine,

Rockwell Hardness Testing Machine is manufactured under strict quality control at all manufacturing stages. This model is suitable for testing hardness of metals and alloys of all kinds, hard or soft, whether flat or round etc. or of irregular shape. This model is having superior design to that of existing conventional Rockwell Hardness Testers &easy to operate still quite sensitive &accurate.

Features :

- Machine is having different Taper front look and superior aesthetic look over conventional Rockwell Hardness Tester.

- Unidirectional Big Dial type auto load selection knob for load selection of loads 60,100 &150 kgf. Most of the important parts are plated to avoid rusting.

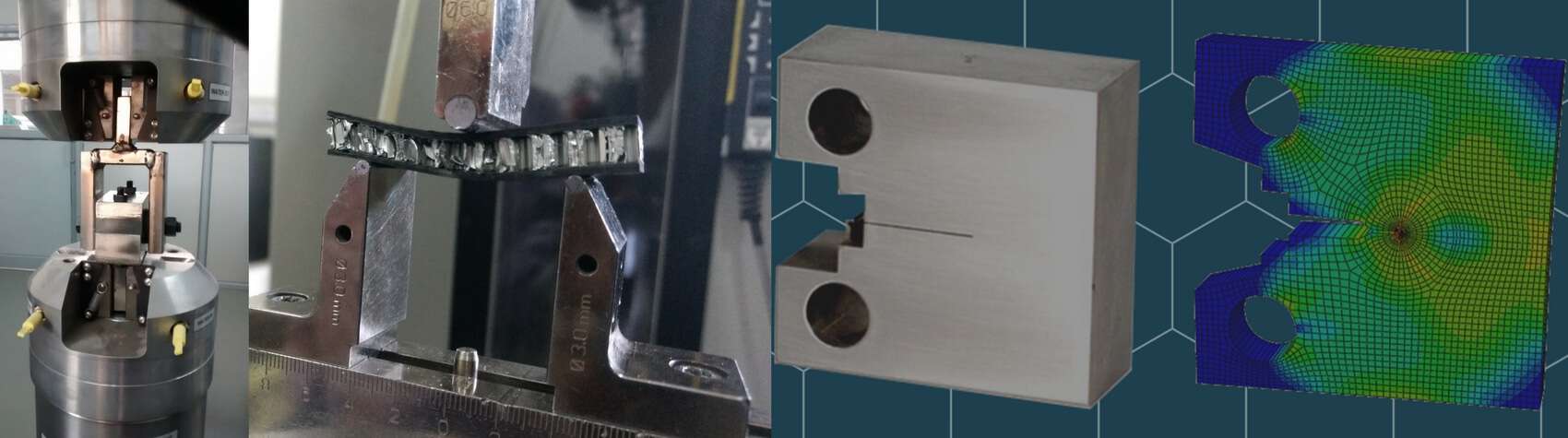

- An antifriction linear bearing is fixed in Hardened & ground stepped bush which will provide perfect vertical movement of diamond holder. Thus the testing of small pin or ball upto 3mm dia is possible.

- All models conform to - IS : 1586, BS 10109-2, ASTM-E-18 & ISO : 6508-2 for Rockwell Test.

Salient Features :

- LCD Graphical Display with 128 x 64 pixels & Results are displayed in BIG Font size

- Minor load is graphically displayed on LCD screen (Minor load auto brake system)

- Provision of Numbers. of tests, mean, standard deviation, maximum, minimum range, individual test hardness numbers in PC Software.

- Dwell Time setting for MAJOR Load 1 to 99 sec & MINOR load dwell time is 1-30 sec.

- 75 Results are stored in the system with automatic result data storage.

- User can enable auto save results storage in system or disable it.

- User can select appreciate scale according to weight selected.

- Motorized Automatic Loading or Manual Loading is selectable.

- Conversion of results from Rockwell to Brinell (HB) , Vickers (HV), Knoop (HK), Tensile Strength (KSI),

- Serial Port for Dot Matrix Printer or EPSON LX 300 +(optional).

- Print result consists of Serial No. Hardness Value and Hardness Scale.

Analogue Rockwell Hardness Testers

Fine make hardness testers model IRS, TRS-150_ TRB, TRB-250 and TSM are manually operated_ These models are designed and developed after years of experience in this field. All the models are manufactured under strict quality at all manufacturing stages.

These models are suitable for testing hardness of metals and alloys of all kinds,. hard or soft, whether flat or round etc_ or of irregular shape. These Testers are simple rn design and easy to operate, still suite sensitive and accurate.

These models strictly conform to iS 3804. BS 891 Part-I &IL ASTM-E-18 for Rockwell test and IS 2281-2005_ BS 240. ASTM-E-10 for Brinell test and IS 5073-1988_ ATM-E-18 for Rockwell Superficial test.

Combined Rockwell Hardness Tester series

Rockwell, Rockwell Cum Brinell, Rockwell cum Superficial Hardness Tester are manufactured under strict quality control at all manufacturing stages. These models are suitable for testing hardness of metals and alloys of all kinds, hard or soft, whether flat or round etc. or of irregular shape. These models are having superior design to that of existing conventional Rockwell Hardness Testers & easy to operate. It is quite sensitive & accurate.

Features :

- FTMPL make Hardness Testers models TRSN, TRSN-B and TRSN-T are manually operated.

- Machine is having different Taper front look & equipped. With big dial gauge and superior aesthetic look over conventional Rockwell Hardness Tester.

- The machine is powder quoted & paint shade does not fade over the years of use.

- Most of the important parts are plated to avoid rusting.

- An antifriction linear bearings is fixed in Hardened & ground stepped bush which will provide perfect vertical movement of diamond holder. Thus the testing of small pin or ball upto 3 mm dia is possible.

- All models conform to - IS : 3804 BS 10109-2 & ASTM-E-18 for Rockwell Test IS : 5073 BS 10198-2 & ASTM-E-18 for Rockwell Superficial Test

Computerised Vickers Hardness Testing Machine

Technical Specification :

| S.No | Description | TV-50-PC | TV-50-IPC | TV-250-PC | TV-250-IPC |

|---|---|---|---|---|---|

| 1 | Loads (Kgf.) | 5, 10, 20,30 & 50 | 5, 10, 20 ,30 & 50 | 5, 10, 20 ,30, 50 for Vickers 62.5, 187.5, 250 for Brinell | 5, 10, 20 ,30, 50 for Vickers 62.5, 187.5, 250 for Brinell |

| 2 | Maximum Test height (mm) | 200 mm | 200 mm | 200 mm | 200 mm |

| 3 | Depth of throat (mm) | 150 mm | 150 mm | 150 mm | 150 mm |

| 4 | Weight Approx. (Kgf) | 180 | 180 | 180 | 180 |

| 5 | Dimension L * W * H mm | 660 * 180 * 850 mm | 660 * 250 * 850 mm | 660 * 250 * 850 mm | 660 * 250 * 850 mm |

| 6 | Connected load | 0.1 KVA, 1 Phase AC, 220V, 50 Hz | |||

Fully In built Computerized Vickers Hardness Tester

| S.No | Description | TV-50-PC | TV-50-IPC | TV-250-PC | TV-250-IPC |

|---|---|---|---|---|---|

| 1 | Loads (Kgf.) | 5, 10, 20,30 & 50 | 5, 10, 20 ,30 & 50 | 5, 10, 20 ,30, 50 for Vickers 62.5, 187.5, 250 for Brinell | 5, 10, 20 ,30, 50 for Vickers 62.5, 187.5, 250 for Brinell |

| 2 | Maximum Test height (mm) | 200 mm | 200 mm | 200 mm | 200 mm |

| 3 | Depth of throat (mm) | 150 mm | 150 mm | 150 mm | 150 mm |

| 4 | Weight Approx. (Kgf) | 180 | 180 | 180 | 180 |

| 5 | Dimension L * W * H mm | 660 * 180 * 850 mm | 660 * 250 * 850 mm | 660 * 250 * 850 mm | 660 * 250 * 850 mm |

| 6 | Connected load | 0.1 KVA, 1 Phase AC, 220V, 50 Hz | |||

Various Types of Flat and Vee Tables

Microscope for and eyepiece for the tester

All Types of Intentor

Calibrated Master Blocks